Against the backdrop of the rapid development of the electric vehicle industry, the electric motor, as the primary power source, directly dictates key vehicle performance metrics such as acceleration capability and driving range. The rotor position sensor, serving as the critical feedback element for motor control, is essential for ensuring precise motor response in scenarios like emergency braking, acceleration, and steering. This is particularly crucial for permanent magnet synchronous motors (PMSMs), which lack physical contact commutators. By providing rotor position information, it determines the timing for current direction switching, thereby ensuring stable motor operation.

| Common Motor Position Sensors for EVs: Resolver and Eddy Current Sensor

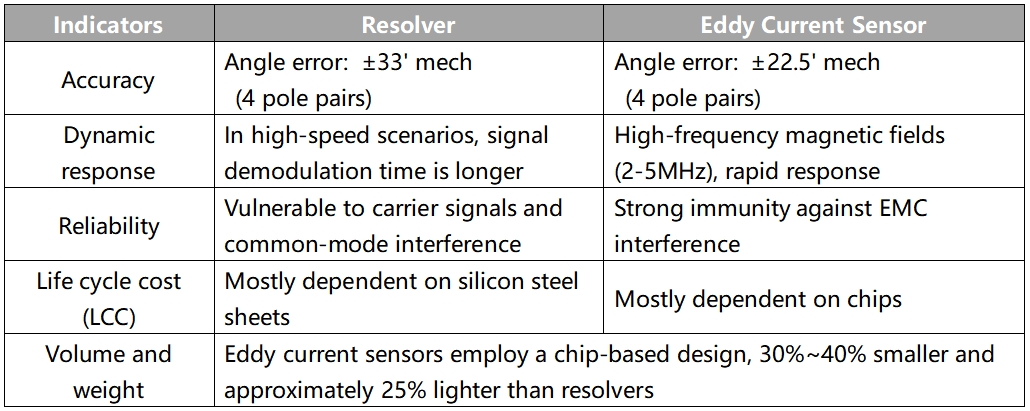

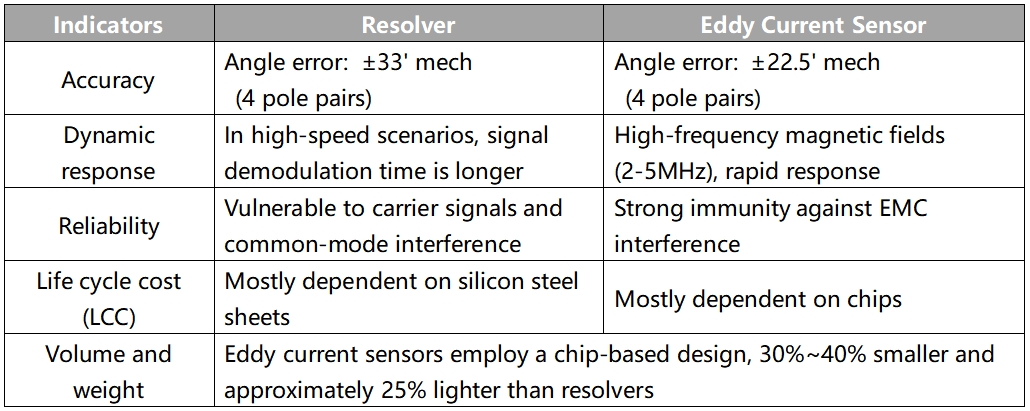

In today’s EV power train systems, resolver has become the mainstream position sensor due to its simple structure, flexible integration, and high accuracy. Meanwhile, eddy current sensor, as an emerging technology, demonstrates significant potential in specific scenarios with its unique performance characteristics. Each possesses distinct advantages in technical features, and users’ choices must be differentiated based on application scenarios. Their key performance indicators are compared below:

| Application-based Selection Guide

On top of the performance indicators above, we learn that resolvers and eddy current sensors each offer their technical adaptability in EV powertrains. The optimal selection requires consideration of the core application demands.

· High-performance vehicles and commercial vehicles: Eddy current sensors are preferred, as their dynamic response, control accuracy, and anti-interference capability meet the requirements.

· Platform-based volume production: Resolvers, with their mature supply chains and simpler installation, are more suitable for large-scale production.

· Emerging motor technology scenarios (such as axial flux motors, ultra-high-speed motors): Eddy current sensors are preferred for their volume and high-frequency response, which empower these new motors to deliver their best performance.

| Kewell M2000-MS E-Motor Emulator—Advanced Position Sensor Simulation Solution for EV Testing

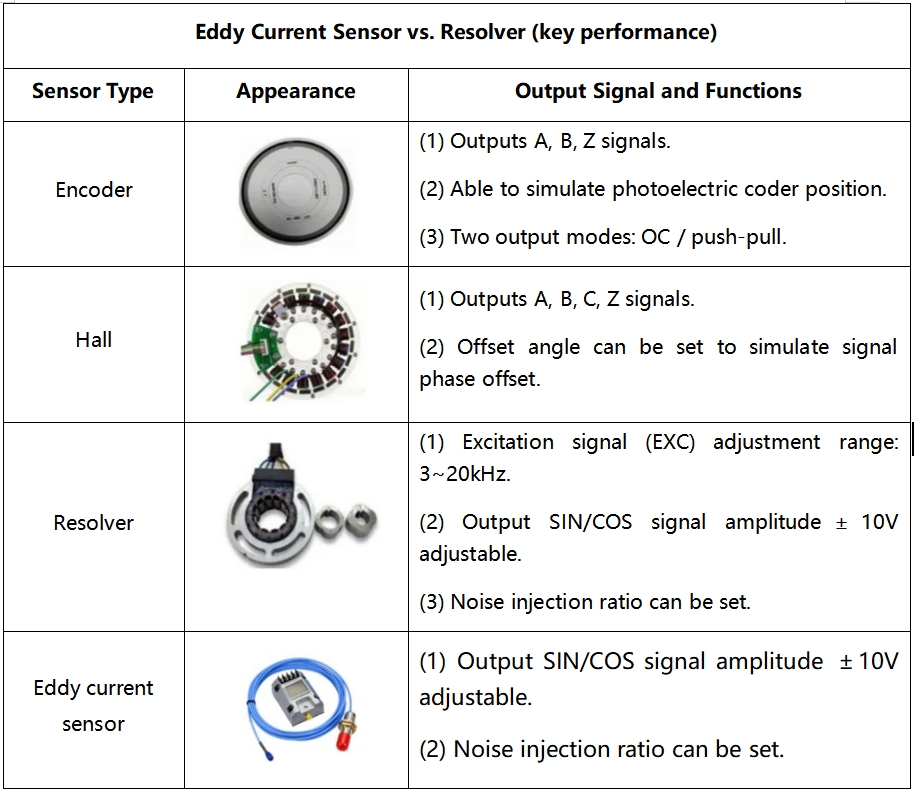

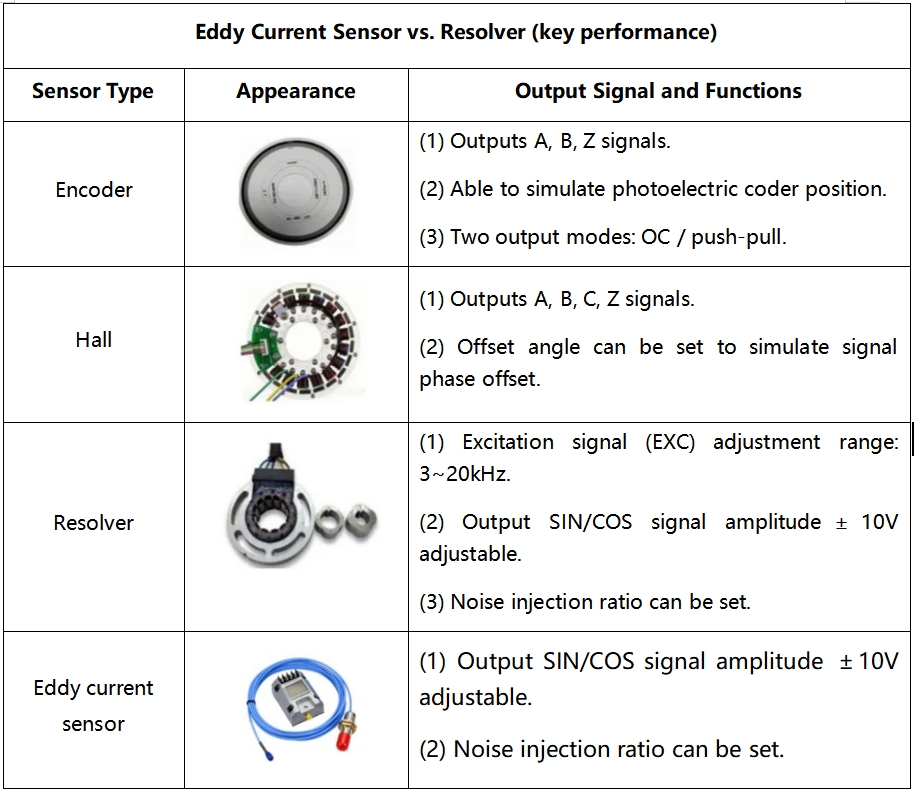

In response to the R&D and testing needs of EV motors and controllers, Kewell has launched the next-generation M2000-MS E-motor Emulator (EME). It can simulate the signal of various position sensors, including encoders, Hall sensors, resolvers, and eddy current sensors, providing an efficient tool for sensor performance validation.

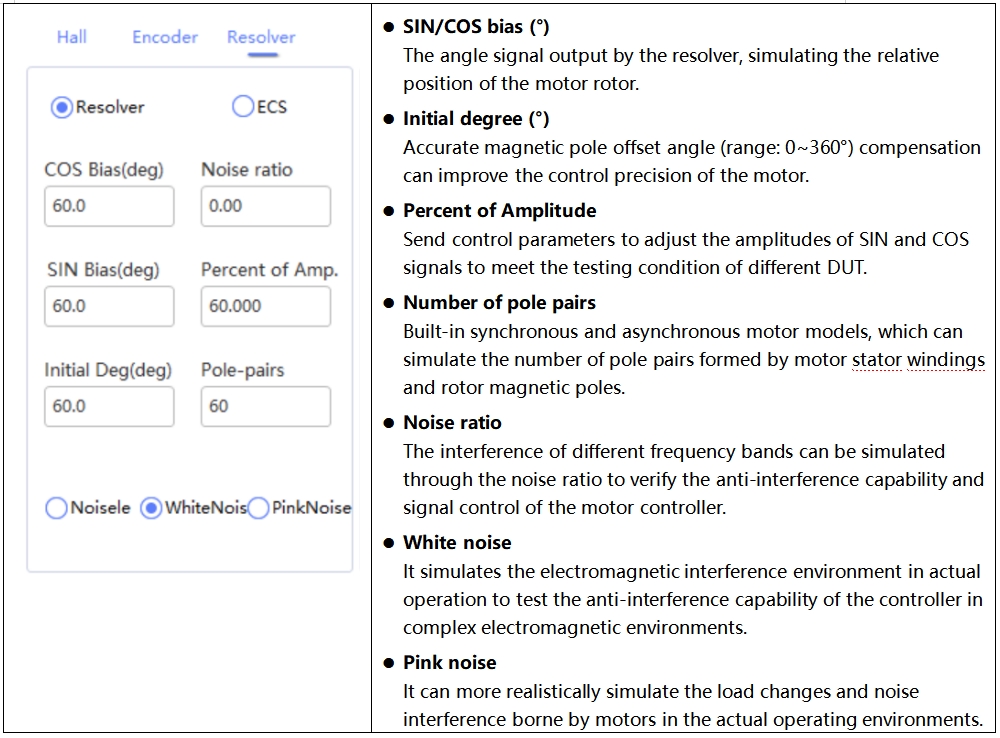

| M2000-MS EME Position Sensors—Resolver & Eddy Current Settings and Core Control Parameters

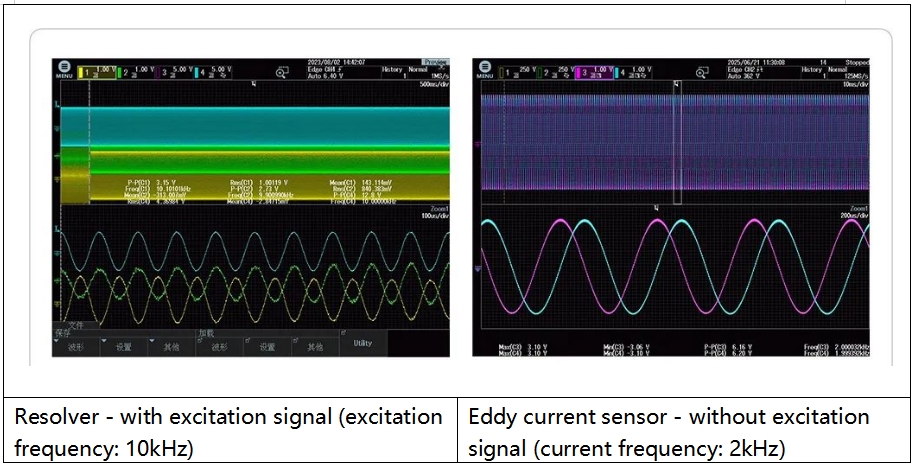

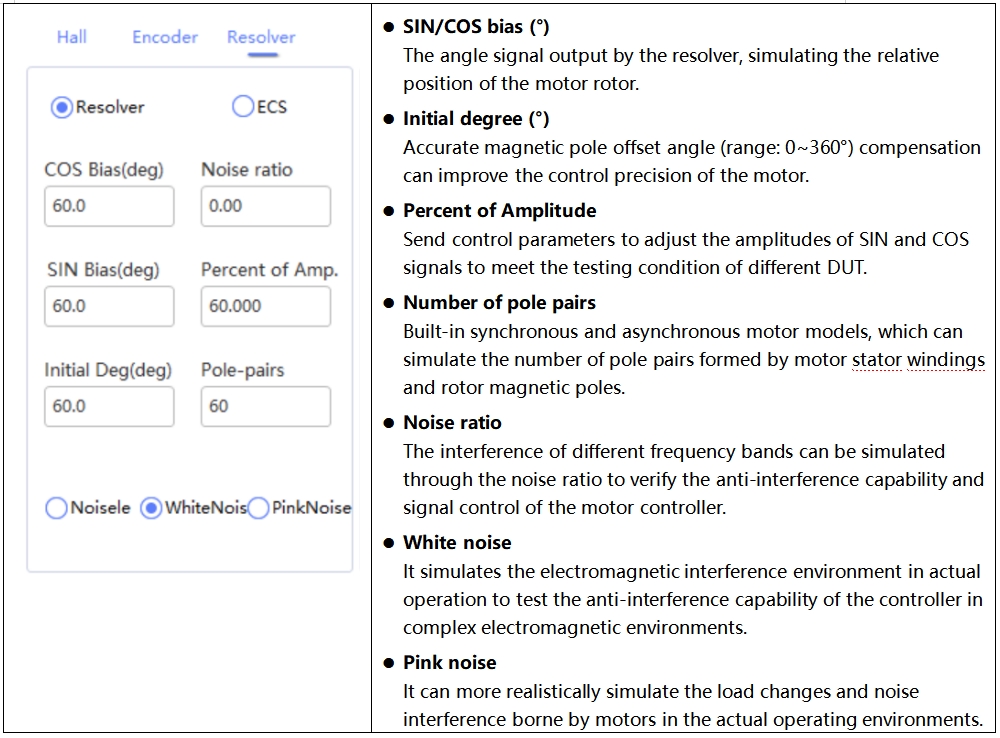

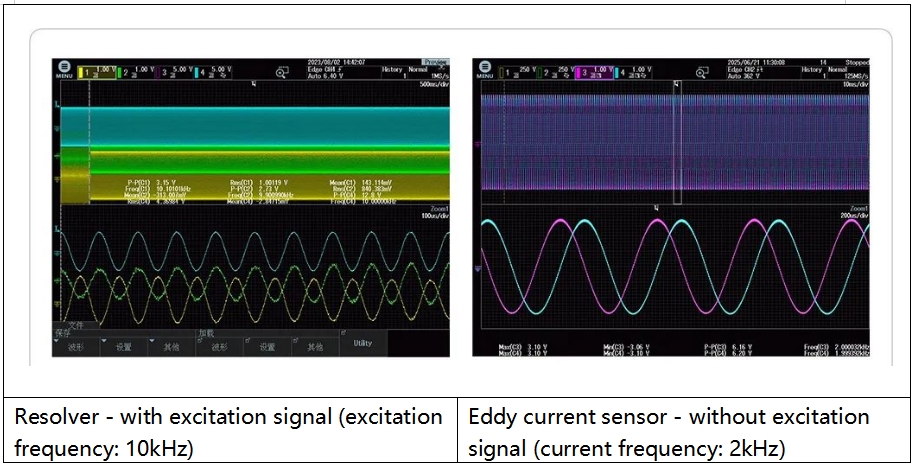

In terms of the function parameters, the EME establishes similar basic control parameters for the resolver and eddy current sensor. The essential difference lies in whether an AC excitation signal is required. The mode can be switched according to different position sensors to meet the testing needs of different devices under test. The simulated waveforms in actual test with resolver and eddy current sensor of the Kewell M2000-MS series EME are as follows:

| Conclusion

Resolvers and eddy current sensors are not mutually exclusive, instead, they form a complementary technology matrix: the former is suitable for volume production scenarios, while the latter is more in line with the needs of high-performance and emerging motor technologies.

As R&D and testing demands of motor controllers escalate across electric vehicles, aerospace, and industrial automation, sensor selection must comprehensively consider motor design parameters (number of pole pairs, RPM, current frequency, etc.), vehicle electromagnetic environment, manufacturing processes, and costs. The Kewell M2000-MS E-motor Emulator, with the ability to simulate multiple types of sensor signals, provides the industry with an efficient and accurate testing solution, contributing to the technological development of electric drive systems.

Position:

Position: